Company Profile

Dongguan Shangtong Hardware Electronics Co., Ltd. was established in 2007. It is a terminal connector enterprise focused on research and development, design, manufacturing, and sales. The company is located in Xicheng Industrial Zone, Hengli Town, Dongguan City, Guangdong Province, with convenient transportation and a beautiful environment.

The company's main products include: reinforced high-current terminals, dual-tube male-female plug terminals, PCB board male plug terminals, ground ring terminals, U-type wiring terminals, embossed copper strips, substrate terminals, round tube waterproof male-female terminals, new energy terminals, pre-insulated terminals, SC copper tube terminals, insulating sleeves and housings, etc. Customized production according to customer requirements is also available. The products are widely used in household appliances, smart home, electronic accessories, energy storage, new energy vehicles, and wire harness industries.

The company has passed ISO9001 and IATF16949 quality management system certifications. The products have obtained multiple utility model certificates and invention certificates, and have also passed UL certification, CQC certification, and comply with RoHS and REACH environmental laws and regulations.

The main production equipment includes: precision high-speed punching machines, fully automatic material collectors, slitting machines, embossed copper strip machines, CCD inspection equipment, automatic welding machines, automatic assembly machines, automatic packaging machines, Japanese Sodick slow wire cutting machines, precision grinders, spark machines, and other related equipment.

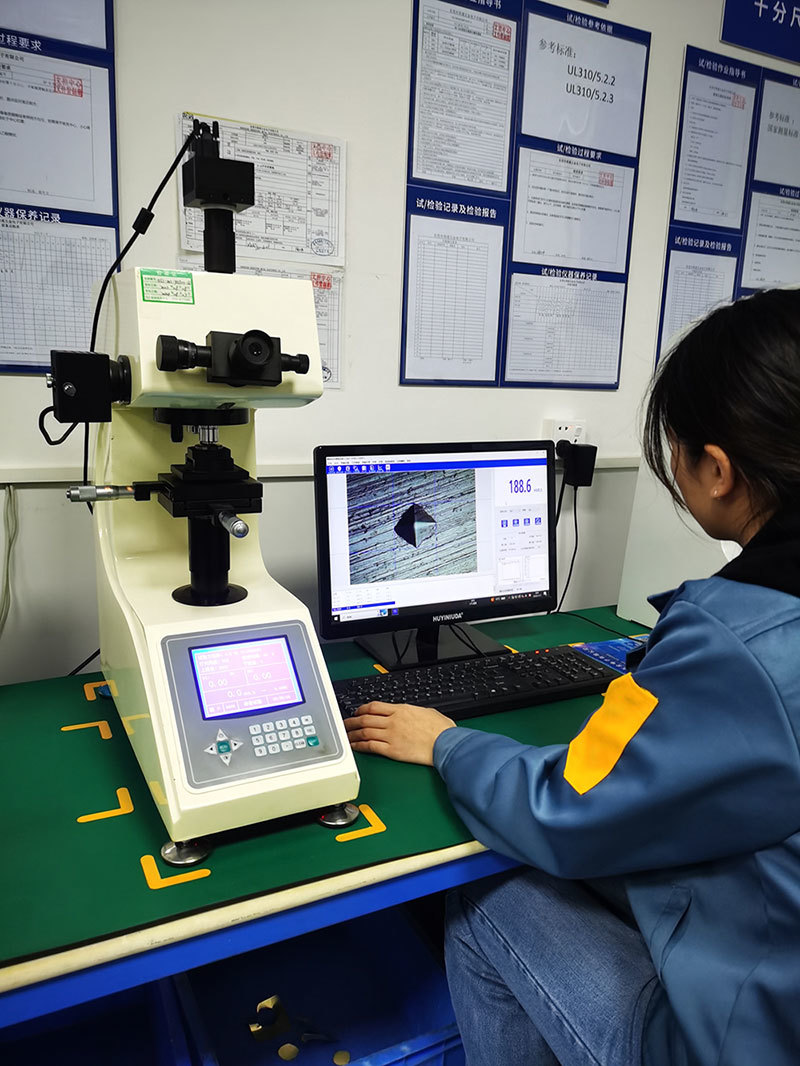

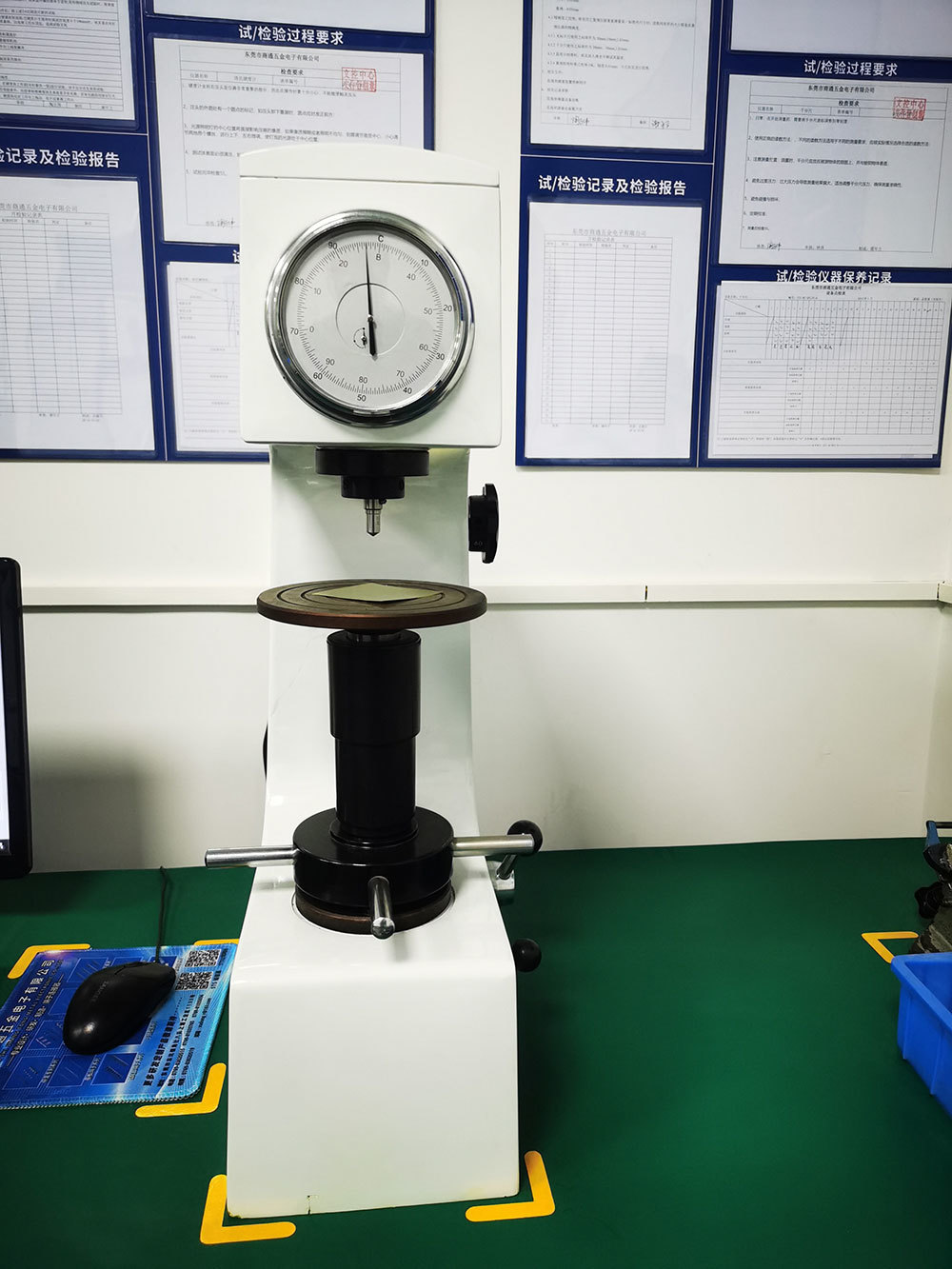

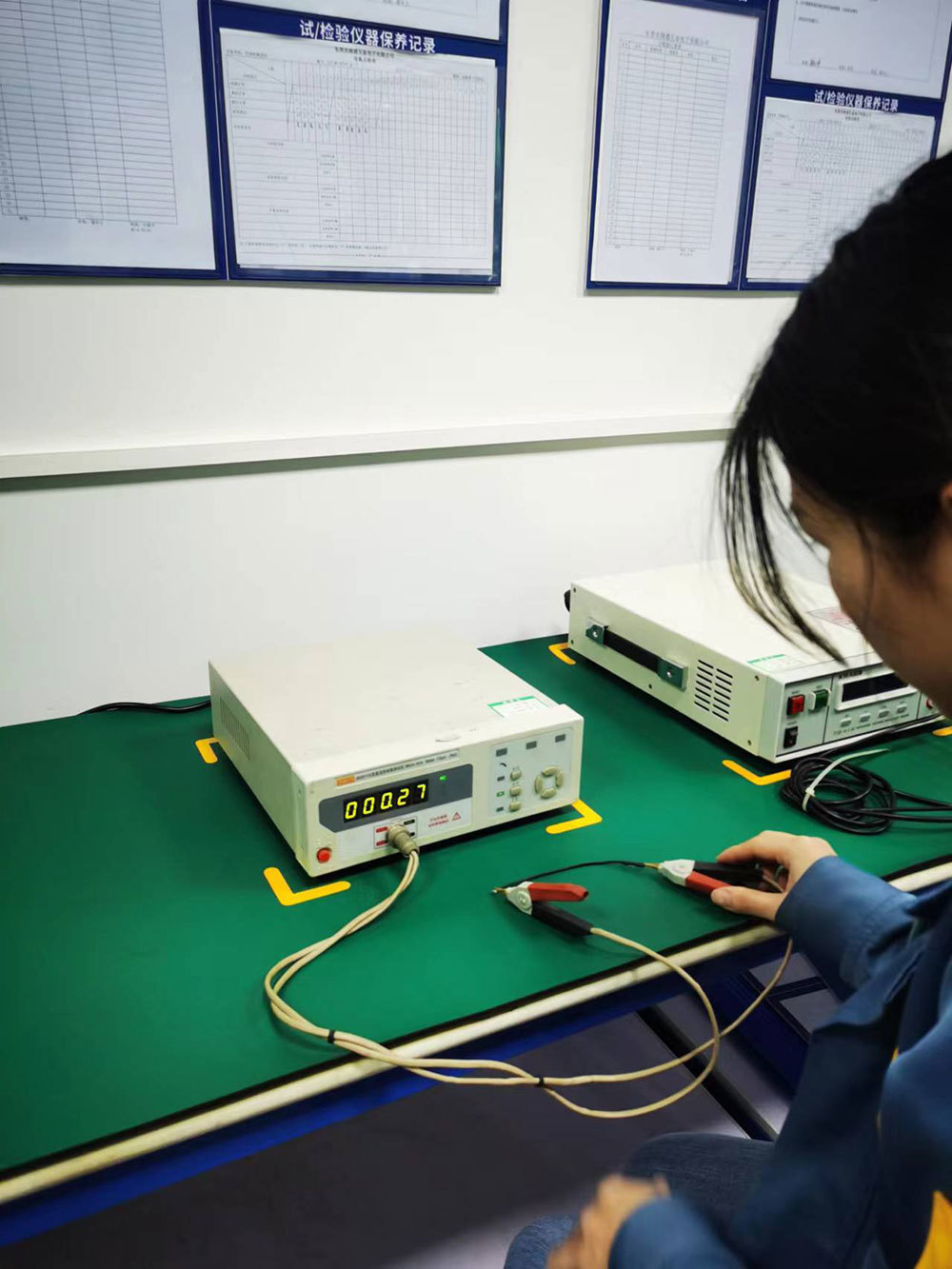

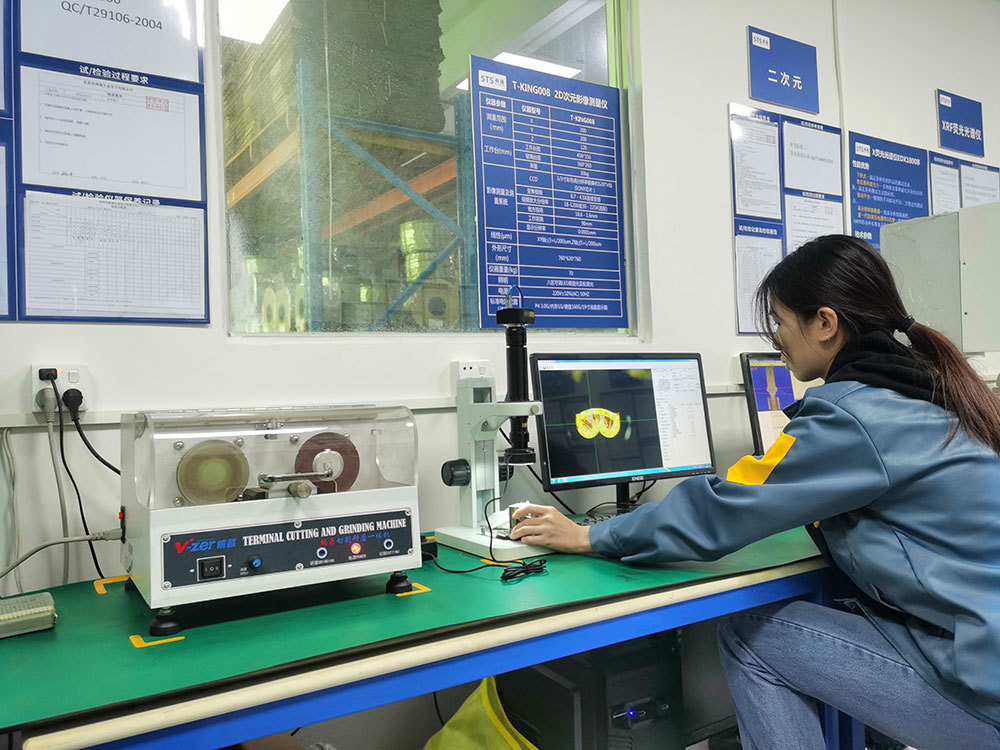

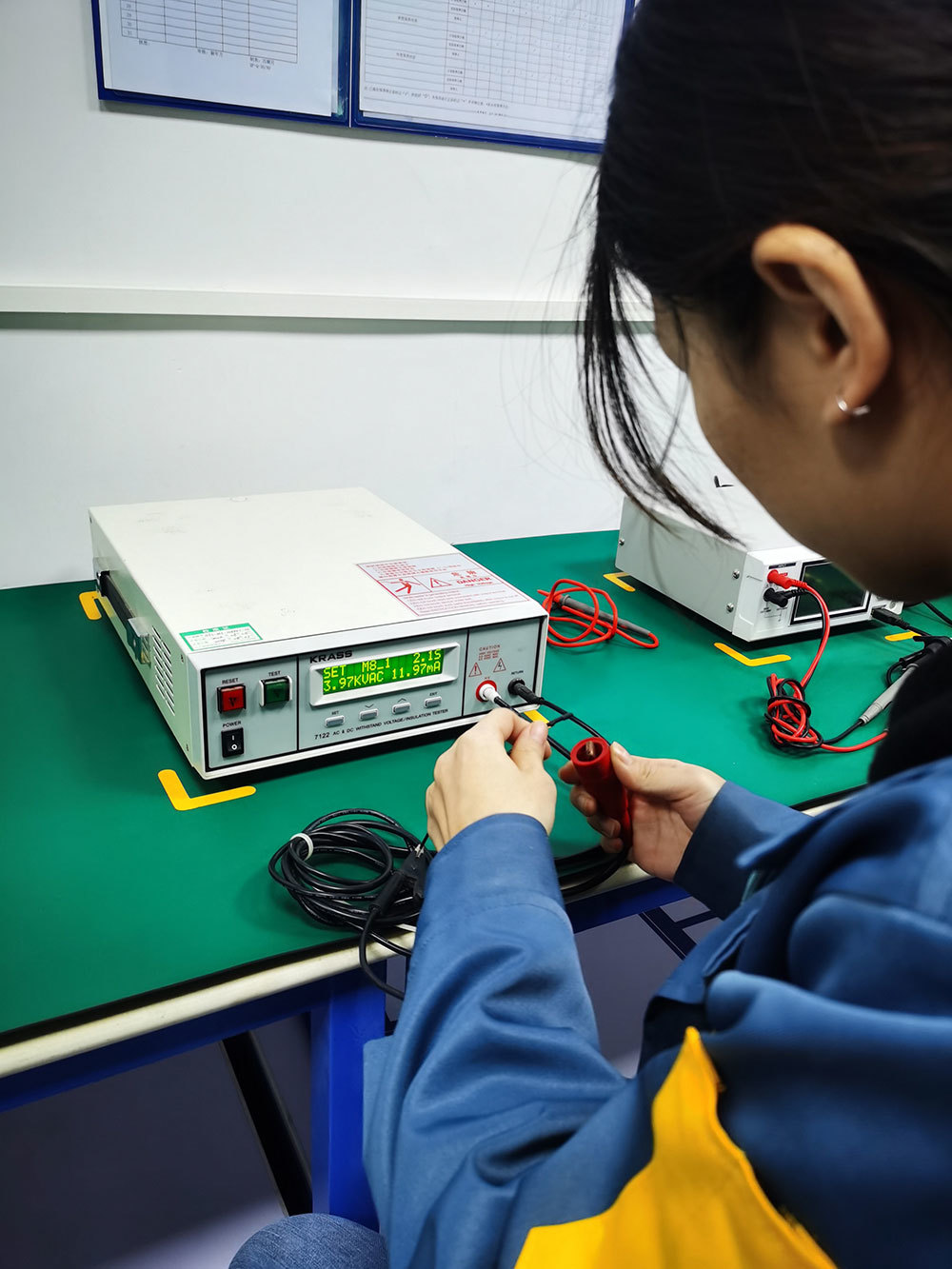

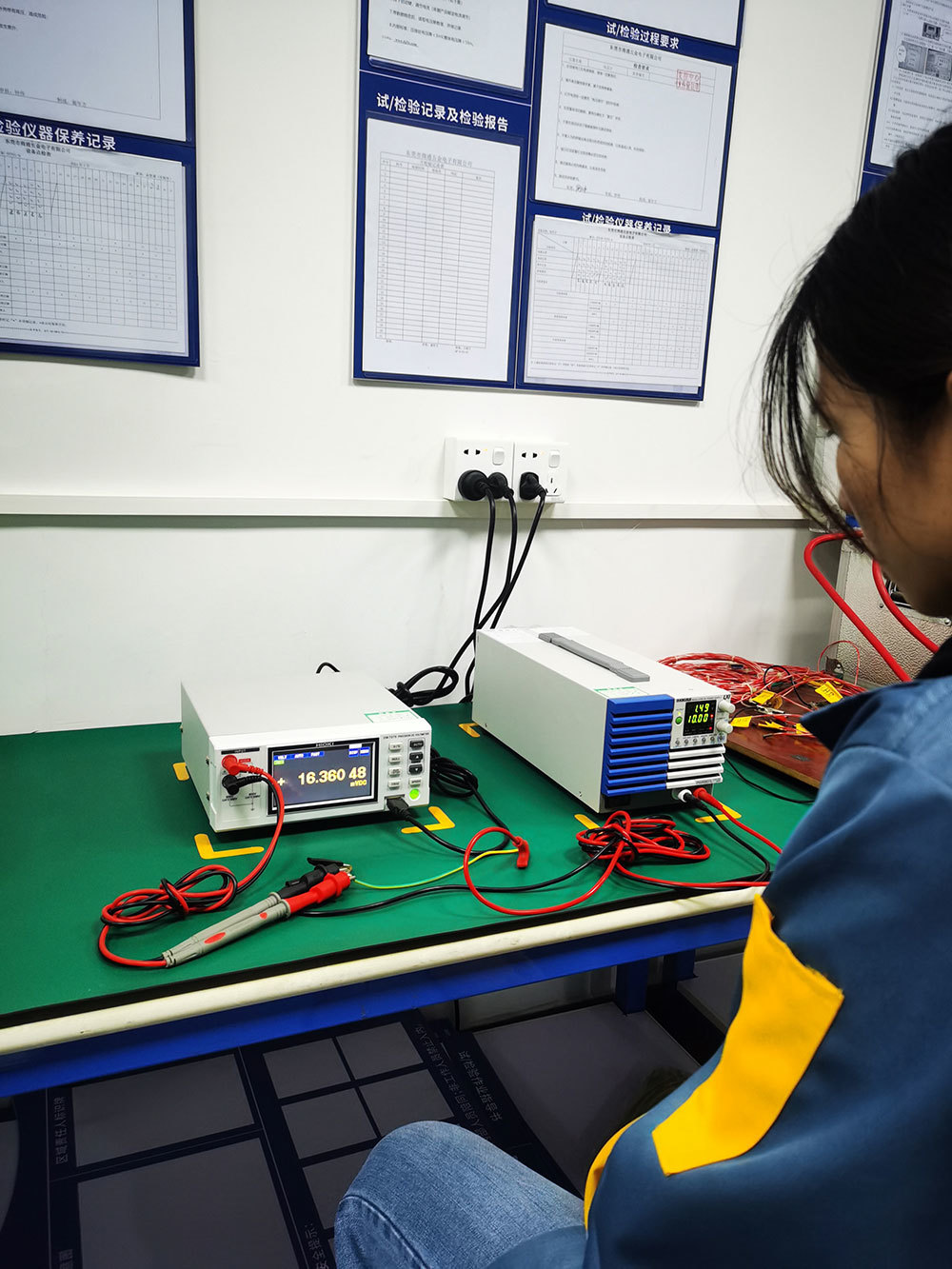

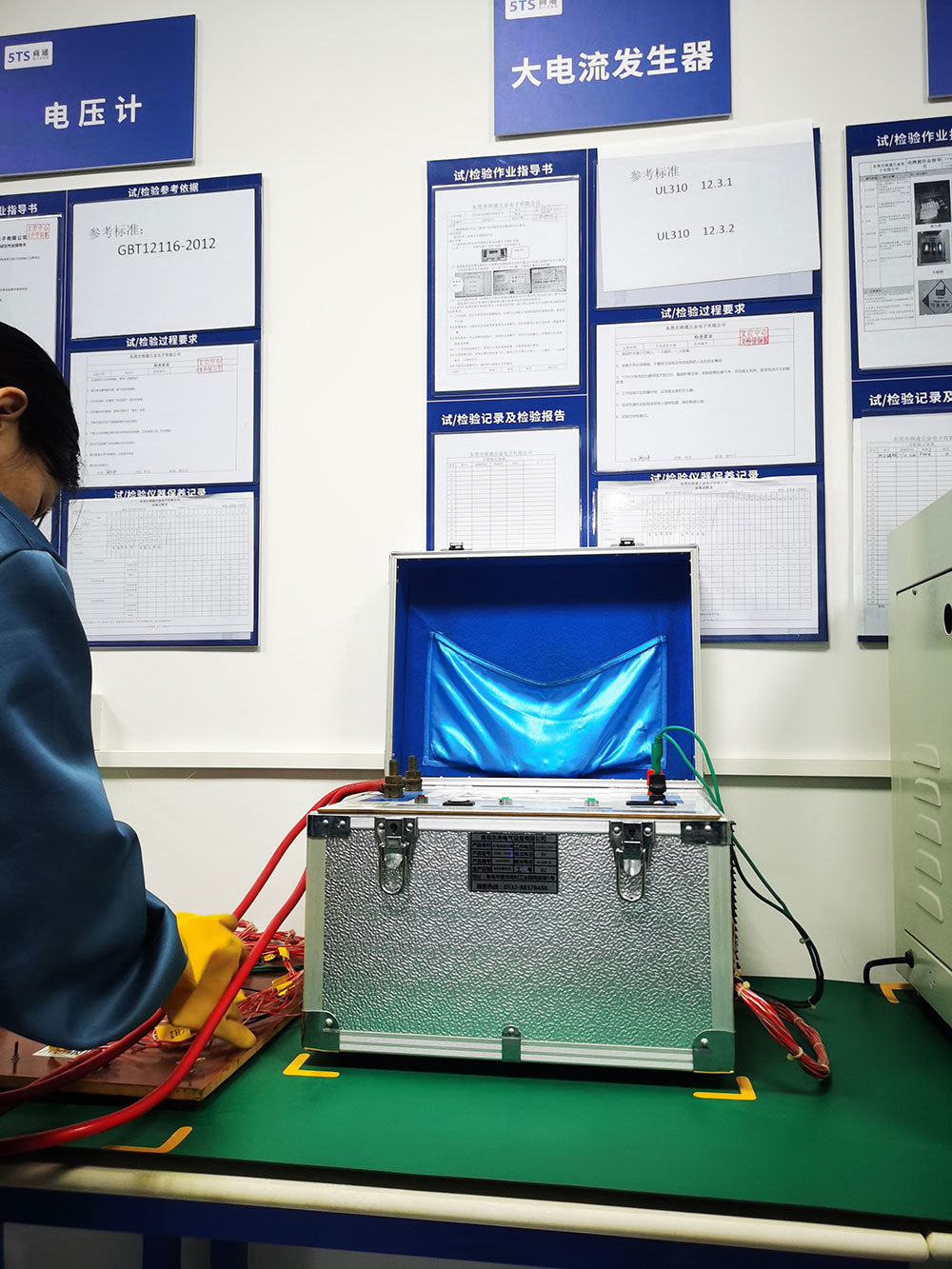

Testing instruments include: X-ray spectrometer, Vickers hardness tester, Rockwell hardness tester, projector, cross-section analyzer, high-current generator, insulation withstand voltage tester, voltage drop tester, resistance tester, fully automatic tensile tester, constant temperature and humidity chamber, needle flame tester, glow wire tester, etc.

In order to maintain a competitive advantage in the market and continuously improve the company's management level while keeping pace with customer development, the company continuously introduces cutting-edge management consulting firms and implements software such as Kingdee ERP, MES, and WMS. Building a digital factory, all products are made from high-quality raw materials sourced from top-tier manufacturers. The company continuously introduces advanced domestic and foreign production equipment and mold processing equipment, capable of meeting large-scale and specialized custom orders, providing a solid guarantee for stable product quality.

The company has established long-term and stable strategic partnerships with many well-known enterprises worldwide. Looking to the future, the company will continue to adhere to the business philosophy of "Quality First, Customer Satisfaction," actively promote technological and management innovation. We will continue to provide customers with higher quality products and services, working together for mutual success!

Company founded in 2007

Company plant area

Company employees

Various types of terminals

Patented technology

Qualification Certificate

Company Showcase

Plant Equipment

Laboratory

Company Panorama

Front Desk

Conference Room

Embossed Copper Tape Workshop

Mold workshop

Wire walking workshop

Cold pressing workshop

Slitting workshop

Stamping workshop

Raw material warehouse

Mold warehouse

Shipping area

Finished Goods Warehouse

Semi-finished product warehouse

Laboratory

Automatic plug-and-pull machine

Glow wire

Vickers hardness tester

Salt spray test machine

Projector

Constant temperature and humidity box

High temperature oven

Tin melting furnace

Spectrometer

Rockwell hardness tester

Insulation resistance tester

Cross section analyzer

Insulation pressure tester

Voltmeter

High current generator